Capabilities

Foundry

Process

Green Sand Process

and No-Bake Process

Capacity

1500 MT

Single Part Weight

400 Grams to 2500 Kg.

Technology

Jolt Squeeze & High Pressure Moulding. OMEGA Plant for No Bake Process.

Current Utilization

1000 MT

Capital Invested (inr)

1400 Million

Machine Shop

Process

CNC Machining

Current Utilization

70%

Technology

Turning, VTL, HMC, HBM, Drilling etc Machining Process

Grey Cast Iron Grades

- EN-GJL -150 to EN –GJL-350

- FG150 to FG400

- Class 20 to Class 50

Ductile Iron Casting Grades

- EN-GJS-350-22 to EN-GJS-800-2

- SG350/22 to SG 800/2

- Grade 60/40/18 to Grade 120/90/02

Weights

Green Sand Casting

0.4 Kg to 150 Kg

No Bake Casting

50 Kg to 2500 Kg

Dimensions

Green Sand Casting

No Bake Moulding

Our Process

Tool Design & Development

In-House Processes: Tool Design and Layout, Methoding Design,

External Process: Tool Manufacturing, Simulation, 2D to 3D Conversion, Tool 3D Development

Casting

Machining

In-House Processes: Machining, Finishing CMM Inspection.

External Process: Non-Destructive Testing.

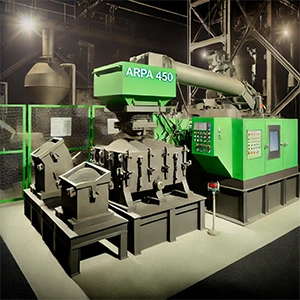

Molding Capability

Green Sand Molding

Arpa 450 Jolt Squeeze Machine with complete sand plant.

Box Size – 650 mm x 600 mm x 200 /200 mm

Sarava Flux – 900 – High Pressure Moulding Line.

Box Size – 1100 x1100 x 250 /250.

No Bake Molding

Sand Mixer with 20 MT/Hr – 1 Omega, 10 MT/Hr – 3 Compaction Table, Sand Reclamation, PLC controlled Additives, Box Size – Variable.

Melting Capability

Induction Furnace

750 Kg Capacity – 2 Induction Furnaces. These are used for Green Sand Process.

1500 Kg Capacity – 1000 KW Dual Track Induction Furnaces. These are used for No Bake Process.

Cupola Furnace

26 Inch & 32 Inch ∅ with 3500Kg per Hour Capacity – 3 – & 5000 Kg per Hour Capacity – 1 Nos., These are used for No Bake Process for Electrical Motor Industry.

Machine & Toolroom

VTL – Yantrang

VTL SKQ 12 TOS Hulin

VTL SKIQ 8 TOS Hulin

VTL SK – 16 TOS Hulin

Radial Drilling Machine

Makino Make HMC

Horizontal Boring San Rocco

Lab

At Shining Engineers, we are having all the test equipment to ensure the Quality of the parts produced.